Solution

Industry 4.0

lndustry 4.0

Realize the Industry 4.0 Revolution Intelligently linking and analysing data with Industrial Internet of Things (IIOT)

The industrial world is confronted with a slew of new challenges. As our resources are limited, we all need to accomplish more with less. To face these challenges on the way to Industry 4.0, digitalization and automation will be key differentiators. The huge amount of data generated by the Industrial Internet of Things (IIOT) must be collected, understood, and used. The Digital Enterprise accomplishes this by merging the physical and digital worlds. As a result, the infinite amount of data helps us to make more efficient use of our limited resources, making the industry more sustainable.

Industry 4.0?

The term “Industry 4.0” refers to the fourth industrial revolution, which encompasses all production domains and is characterised by sophisticated manufacturing technologies for data capture, optimization, and deployment.

Simply put, Industry 4.0 transforms manufacturing into “smart” factories. Industrial Internet of Things (IIOT) technology, artificial intelligence, and cyber-physical systems all work in harmony, communicating and adjusting continuously. Businesses that properly appreciate and capitalise on these advantages will be best equipped to meet the challenges ahead.

Industry 4.0 = Value Creation

While value is created in different ways depending on the maturity continuum, incremental value is available to every manufacturer—but it must be rooted in incremental improvements to the current capabilities.

The trick is to reorient the thinking. Rather than focusing exclusively on certain technology features or tools, let the value creation objectives guide you. A single initiative for improvement in a specific functional area. Even minor functional changes have repercussions throughout the company. These small changes should be made in the context of your company’s larger Industry 4.0 vision, strategy, and roadmap in order to show a real return on investment.

The Three I’s of Industry 4.0 Innovation

Synergic growth under different business scenarios to be truly transformative

Incremental

Iterative

Integrated

01

Incremental

Renovation, not reinvention

02

Iterative

Experiment, respond & adapt

03

Integrated

Cross-function Collaboration

What we deliver

Our multidisciplinary knowledge is founded on extensive technical, methodological, and technological skills, as well as access to industry-leading digital benchmarks.

Usher in a paradigm shift in terms of efficiency and value development

Businesses that make the best use of Industry 4.0 technologies outperform their competitors and accelerate their growth.

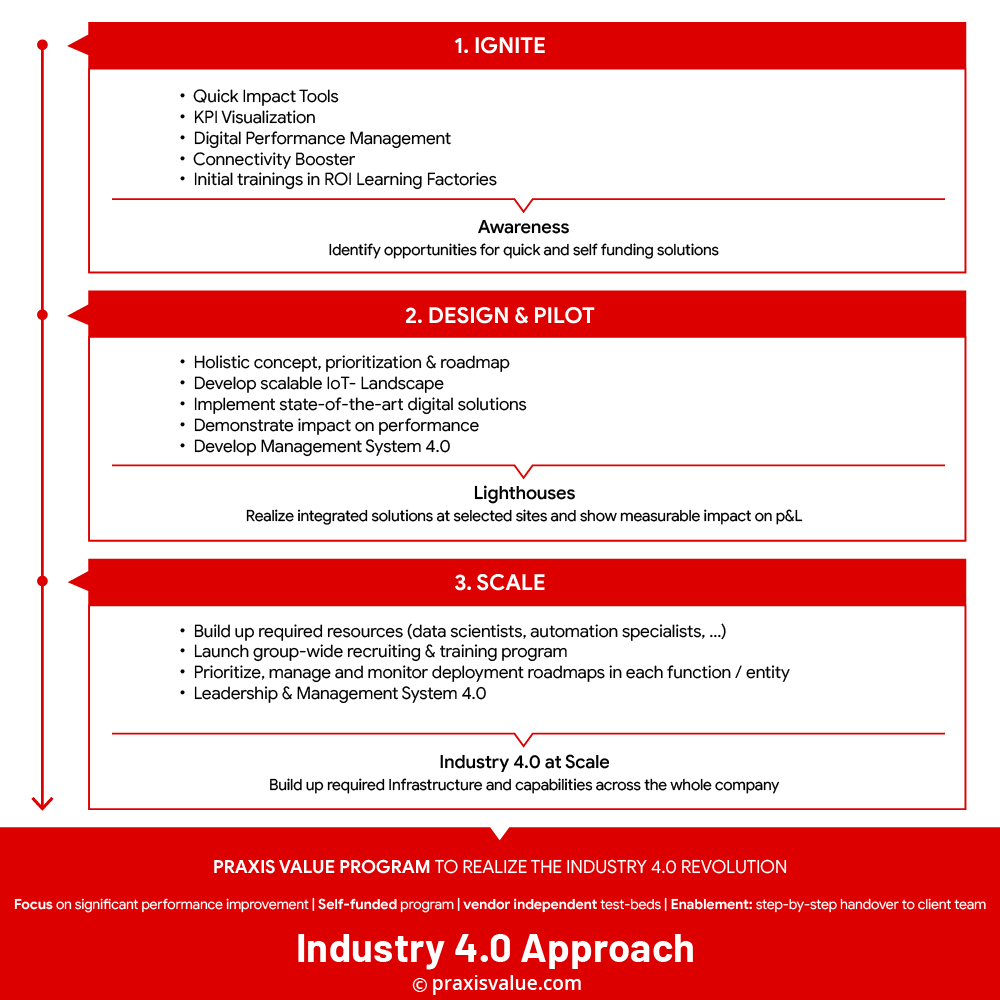

Identify opportunities for quick and self – Funding Solutions

- Quick impact tools

- KPI Visualization

- Digital Performance Management

- Connectivity Booster

Realize integrated solutions & derive measurable impact on P&L

- Holistic concept, prioritization & roadmap

- Develop IOT – Scalable Landscape

- Implement state of art digital solutions

- Develop Management System 4.0

Build of infrastructure & capabilities across the organization

- Build up required resources (Data Scientists, Automation specialties, …)

- Launch group wide recruiting & training program

- Prioritize, manage and monitor deployment roadmaps

- Leadership and Management System 4.0

Unlocking Value Through Industry 4.0

10% – 20% Productivity Increases

(Cost of conversion Costs)6% – 12% Productivity Increase

Total Manufacturing Costs

15% – 30% Productivity Increases

(Cost of conversion Costs)- 4% – 09% Productivity Increase

Total Manufacturing Costs

15% – 30% Productivity Increases

(Cost of conversion Costs)10% – 20% Productivity Increase

Total Manufacturing Costs

15% – 30% Productivity Increases

(Cost of conversion Costs)06% – 12% Productivity Increase

Total Manufacturing Costs

15% – 30% Productivity Increases

(Cost of conversion Costs)15% – 20% Productivity Increase

Total Manufacturing Costs

- 10% – 20% Productivity Increases

(Cost of conversion Costs) - 05% – 10% Productivity Increase

Total Manufacturing Costs

Our Approach

We initiate by doing a thorough analysis of current state and your requirements, then offer and implement an appropriate, reliable solution.

Proven Outcomes

Client Results - Case Study

Industry – Industrial Engineering

Our client was facing issues when it came to optimizing a production plant for dashboards: the entire process chain, as well as all risk elements in production and supplier management, had to become more transparent. At the same time, because a sensitive material was being processed, even minor manufacturing errors resulted in complete output rejection; the scrap rate had to be lowered

Why choose Praxis Value

Better Productivity

Praxis Value assists industrial firms of all sizes in utilizing smart manufacturing to enhance their operational activities and production.

Improved Workflow

We provide strategies and solutions that enable you to increase productivity and value creation on your projects.

Hidden Insights

Our dedicated team of industry experts will ensure that you get the most out of Industry 4.0, the Internet of Things, and advanced analytics.

Experienced Workforce

Our firm is comprised of seasoned senior analysts from a variety of industries and data scientists skilled in advanced statistical modelling.